Lean problem solver: Suggest solutions for lean manufacturing challenges

With lean problem solver, teams can effortlessly pinpoint improvement opportunities, track metrics, and implement changes for better efficiency.

Similar apps

Maximize lean manufacturing solutions with our powerful web app

Unlock the potential of continuous improvement initiatives to drive efficiency and performance in your manufacturing processes

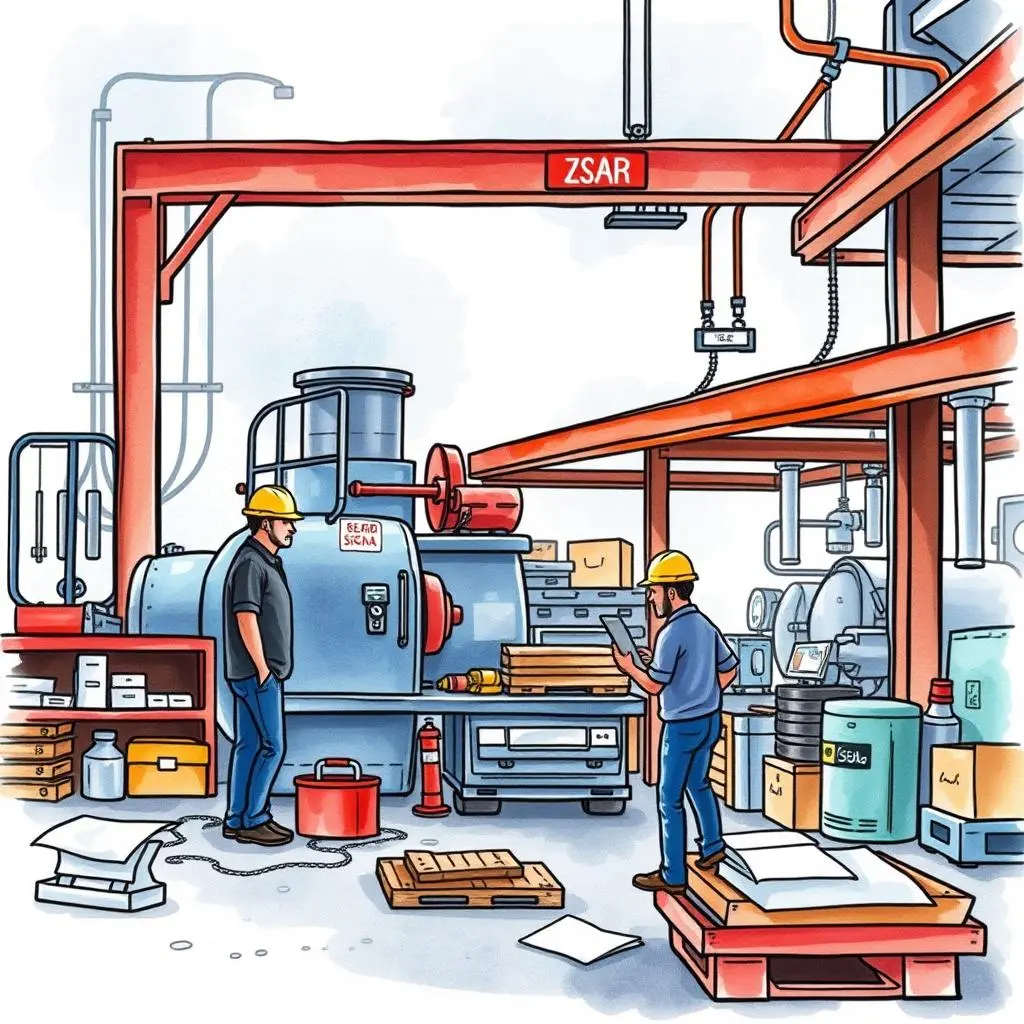

Streamlined input forms for comprehensive data capture

Our app provides a structured set of input fields, allowing users to enter essential information such as the title, description, process ID, expected outcomes, and more. This organized approach ensures that all relevant details are captured, enabling more precise and actionable AI-generated solutions.

Enhanced collaboration among team members

With dedicated fields for team members involved in each initiative, our web app facilitates collaboration and enhances communication among stakeholders. By effectively tracking contributions and responsibilities, your team can evolve their lean projects seamlessly while maintaining accountability throughout the Six Sigma implementation process.

Risk identification and management

Users can efficiently document potential risks associated with each improvement opportunity through our intuitive risk field. By identifying challenges early on, teams can develop mitigation strategies leading to a smoother implementation process and greater success rates in achieving operational excellence.

Ai-driven insight for continuous improvement

Leverage the power of our advanced language model to suggest tailored actions or next steps based on comprehensive user inputs. Ensure that your improvement initiatives are grounded in data-driven insights, enhancing problem-solving capabilities while minimizing guesswork during critical phases of Six Sigma implementation.

Informed decision-making with relevant metrics

By entering specific metrics or KPIs into our platform, users can track progress quantitatively. This feature empowers teams to make informed decisions based on real-time data analytics that measure success against set benchmarks within lean manufacturing practices.

Additional information

Best for: Continuous Improvement Manager, Six Sigma Specialist, Process Improvement Analyst, Lean Manufacturing Consultant, Quality Improvement Engineer