Efficiency enhancer: Improve operational efficiency through identified opportunities

Use efficiency enhancer to manage six sigma projects, identify improvements, and measure success easily with your team's collaboration.

Similar apps

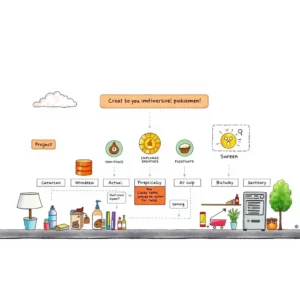

Maximize operational efficiency with our web app

Streamline your six sigma implementation effortlessly

Comprehensive input fields for detailed insights

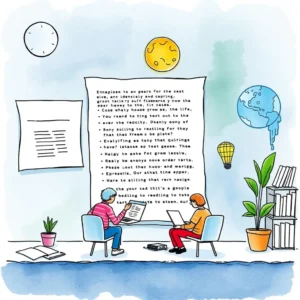

Our app supports extensive text input across numerous fields to ensure comprehensive data capture. Users can input critical information such as project titles and team details, facilitating a thorough understanding of improvement opportunities and ensuring no significant detail is overlooked.

Structured guidance for enhanced project planning

The structured format guides users through each step of the Six Sigma process by prompting essential inputs like current processes and identified problems. This organized approach helps Continuous Improvement Managers streamline project planning, facilitating clear communication and actionable insights within teams.

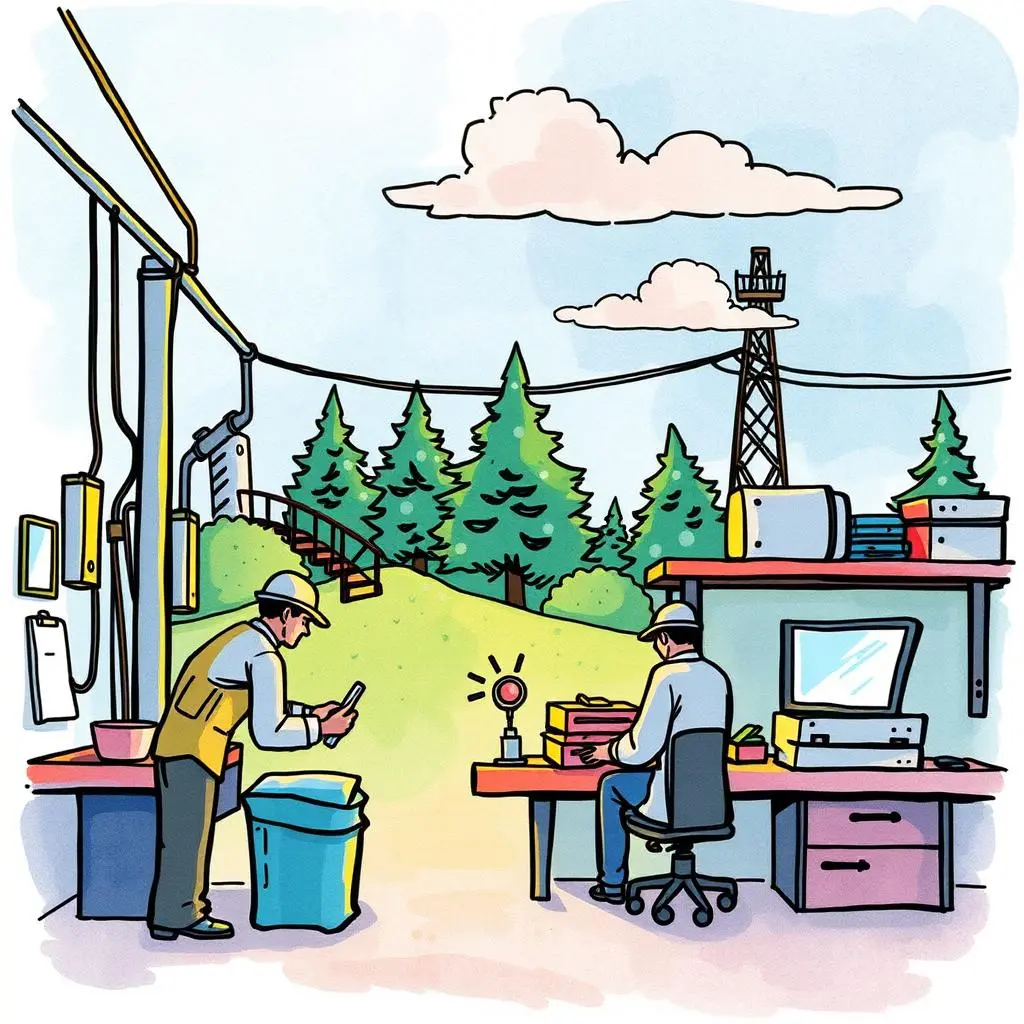

Focused metrics for success measurement

Enter specific metrics to measure improvement success directly within the app. This feature enables Process Improvement Specialists to define targeted outcomes, ensuring that every project has measurable objectives which are easy to track, leading to enhanced accountability and results in manufacturing processes.

Risk identification for proactive problem solving

Users can document potential risks or challenges related to their projects in designated fields. By acknowledging these issues upfront, Lean Manufacturing Engineers can develop proactive strategies for mitigation, fostering a culture of continuous improvement and resilience within the team.

Customizable notes section for flexibility

An additional notes field allows users to enter relevant comments or observations throughout their projects. This flexibility gives Quality Improvement Coordinators a space to capture insights or recommendations that may enhance future Six Sigma initiatives, promoting ongoing learning and adaptation.

Additional information

Best for: Continuous Improvement Specialist, Six Sigma Coordinator, Process Improvement Analyst, Lean Manufacturing Consultant, Quality Improvement Manager