Adaptive maintenance schedule generator: Tailor schedules to dynamic production needs

The adaptive maintenance schedule generator helps streamline equipment upkeep by scheduling tasks, tracking priorities, and assigning technicians easily.

Similar apps

Crafting optimal maintenance schedules for enhanced production efficiency

Streamline your maintenance scheduling process for unmatched productivity in manufacturing and production environments

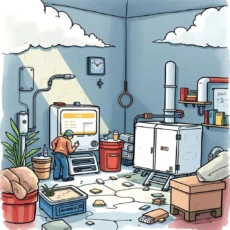

Effortlessly input equipment details

Easily enter essential information like equipment name or ID, maintenance task descriptions, scheduled dates, and technician names. Our user-friendly interface minimises data entry time, empowering you to focus on critical tasks while ensuring each equipment detail is accurately recorded for seamless maintenance planning.

Dynamic scheduling with priority levels

Manage priority effectively by assigning levels to each maintenance task: High, Medium, or Low. This feature enables you to prioritize urgent tasks seamlessly while optimizing the overall schedule. By aligning resources with urgency, your production can continue smoothly without unexpected disruptions.

Capture essential maintenance history

Record vital dates including last maintenance and next due dates effortlessly. This feature helps maintain comprehensive oversight of equipment performance history and future needs. By monitoring maintenance timelines, you can prevent downtime and ensure that every piece of equipment is properly cared for.

Tailor maintenance tasks with special instructions

Incorporate specific guidelines by entering any special instructions or notes relevant to the tasks assigned. This ensures technicians are well-informed about unique requirements before starting a job. Clear communication promotes efficiency in execution while reducing the risk of errors during the maintenance process.

Additional information

Best for: Maintenance Planner, Equipment Maintenance Coordinator, Maintenance Scheduler, Maintenance Operations Specialist, Preventive Maintenance Analyst