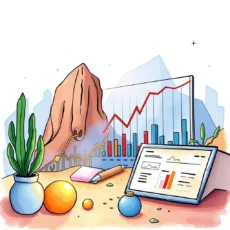

Defect trend reporter: Create reports on defect trends over time

Use the defect trend reporter to analyze trends, log defects, and improve quality in manufacturing, ensuring better production outcomes.

Similar apps

Comprehensive overview of defect trend reporting features

Elevate your quality control efforts with powerful reporting tools

Input defect descriptions seamlessly

Effortlessly input detailed defect descriptions to ensure clarity in reporting. This feature allows users to capture specific issues encountered during the manufacturing process, enabling precise analysis and trend identification over time.

Categorize defects for better insights

With the option to categorize defects such as mechanical or electrical, users can streamline their reports. This targeted categorization helps in aggregating data for a more nuanced understanding of recurring issues, contributing to improved preventative measures.

Log occurrence dates accurately

Enter event dates in a standardized format (MM/DD/YYYY) to maintain consistency across reports. Documenting when defects occur aids in identifying patterns and timelines, critical for effective trend analysis and quality improvements.

Track assembly line metrics

Inputting assembly line numbers provides context that is essential for root cause analysis. By linking defects to specific lines, quality control analysts can evaluate performance variances and implement necessary adjustments efficiently.

Record operator information effectively

Including the operator’s name enhances accountability within production processes. This feature fosters a culture of responsibility while aiding in recognizing training needs based on defect frequency and operator performance.

Assess severity levels clearly

Utilizing severity levels like low, medium, or high enables prioritized responses to defects. Proper classification facilitates quicker reaction times for critical issues while aiding continuous improvement efforts through focused follow-up actions.

Detail corrective actions taken

By recording corrective actions taken after defect identification, users can monitor the efficacy of measures implemented. This ensures that lessons learned contribute towards future refinements in processes and reduces recurrence of issues.

Add comments for comprehensive reporting

The option to include additional observations enables further nuance in reporting. Analysts can document insights or peculiarities surrounding a defect, enriching data context that enhances overall trend analysis outcomes.

Additional information

Best for: Quality Control Analyst, Quality Assurance Specialist, Manufacturing Process Analyst, Trend Analysis Technician, Quality Control Data Analyst