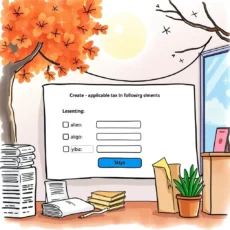

Maintenance review model: Analyze and improve maintenance schedules directly

The maintenance review model helps you schedule and track maintenance tasks, ensuring timely updates and technician accountability.

Similar apps

Analyzing and enhancing maintenance schedules for optimal operation

Revolutionizing your maintenance scheduling with text input

Comprehensive input fields for optimal analysis

Our web app features extensive input fields that allow users to enter critical information such as maintenance task descriptions, scheduled dates, durations, and technician details. These fields ensure all necessary data is captured, leading to accurate analysis and improvement of maintenance schedules.

Dynamic prioritization of maintenance tasks

Users can specify priority levels for each maintenance task, categorizing them as high, medium, or low. This dynamic prioritization feature aids in effective planning and decision-making, ensuring that essential tasks receive attention first and operations remain smooth in the manufacturing environment.

Insightful feedback on previous maintenance

By providing a section to note issues encountered during the last maintenance event and the last maintenance date, our tool delivers valuable insights into historical performance. This feedback loop helps users refine future scheduling based on actual experiences and improve overall efficiency.

Customizable special instructions for unique needs

With a field dedicated to special instructions or notes, users can include unique requirements for each maintenance task. This customization ensures that technicians are well-informed about specific needs or challenges prior to commencing work, enhancing readiness and effectiveness in operational tasks.

Enhanced frequency tracking for proactive management

The application allows users to enter the frequency of maintenance—be it weekly or monthly—which promotes proactive management of equipment upkeep. Regular tracking of these frequencies enables schedulers to anticipate upcoming tasks better and maintain consistent operational standards in the production line.

Additional information

Best for: Maintenance Scheduler, Maintenance Coordinator, Production Maintenance Planner, Assembly Line Maintenance Supervisor