Assembly line maintenance manager: Organize maintenance reviews for assembly processes

Keep your assembly line running smoothly with the assembly line maintenance manager. Schedule tasks, track issues, and assign technicians effortlessly.

Similar apps

Streamline your assembly line maintenance reviews efficiently

Optimize your production processes by managing maintenance reviews seamlessly within your team

Simplified task input for easy management

Easily enter detailed information about each maintenance task, including descriptions, scheduled dates, and special instructions. This feature ensures that every technician is well-informed and prepared for upcoming maintenance, leading to reduced downtime and enhanced productivity on the assembly line.

Comprehensive scheduling for effective planning

Schedule maintenance with precision by setting specific dates and durations for each task. This allows maintenance supervisors to allocate resources effectively, minimizing disruptions in the production process while ensuring that all necessary tasks are completed promptly.

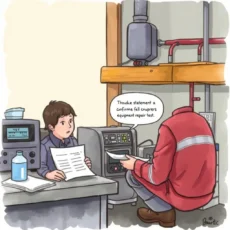

Accountability through assigned technicians

Designate responsible technicians for each maintenance task, creating clear accountability within your team. By knowing who is in charge of what, you can streamline communication and ensure that every aspect of the maintenance process is handled efficiently.

Prioritize tasks to manage workflow

Set priority levels (High/Medium/Low) for each maintenance request to effectively manage workflow. This feature ensures that critical tasks receive immediate attention while allowing less urgent issues to be scheduled accordingly, contributing to smoother operations on the assembly line.

Historical insights for informed decisions

Keep track of last maintenance dates and previous issues encountered with equipment through concise input fields. This allows supervisors to make better-informed decisions based on historical data, aiding in proactive maintenance strategies and preventing future breakdowns.

Additional information

Best for: Maintenance Scheduler, Production Maintenance Coordinator, Assembly Maintenance Planner, Equipment Maintenance Analyst, Maintenance Operations Specialist