Defect findings formatter: Organize and format defect information clearly

Use the defect findings formatter to log defects, track severity, and streamline corrective actions for improved quality control.

Similar apps

Organize and present defect information efficiently

Streamline your defect analysis process

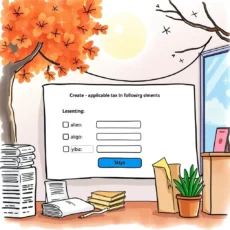

User-friendly text input for defects

Easily enter defect descriptions into the app, ensuring that all relevant details are captured. The structured input fields allow users to specify severity levels, defect occurrence dates, locations, responsible team members, and corrective actions. This promotes clear communication among stakeholders and enhances overall quality control.

Customizable severity levels for accurate reporting

Define defect severity as Low, Medium, or High to prioritize issues effectively. By categorizing defects based on their severity, quality control analysts can focus on critical problems first. This feature enhances reporting accuracy and ensures that the most impactful defects are addressed promptly.

Comprehensive date field management

Utilize dedicated fields to record both the date of defect occurrence and the follow-up date. This ensures a systematic tracking process of issues over time, providing insights into patterns or recurring problems in production. It enables teams to implement timely corrective actions based on historical data.

Clear location identification for root cause analysis

Specify where defects occur by entering precise location information such as the production line or machine ID. This granularity assists teams in identifying specific areas that may require attention or improvement, facilitating more effective root cause analysis during defect investigations.

Actionable follow-up insights

Record details on corrective actions taken alongside additional comments or observations related to each defect. These insights help manufacturing quality specialists assess the efficacy of solutions implemented. Keeping track of experiences supports continuous improvement efforts in quality assurance protocols within production environments.

Additional information

Best for: Quality Control Analyst, Defect Reporting Specialist, Quality Assurance Inspector, Defect Analysis Engineer, Manufacturing Quality Technician