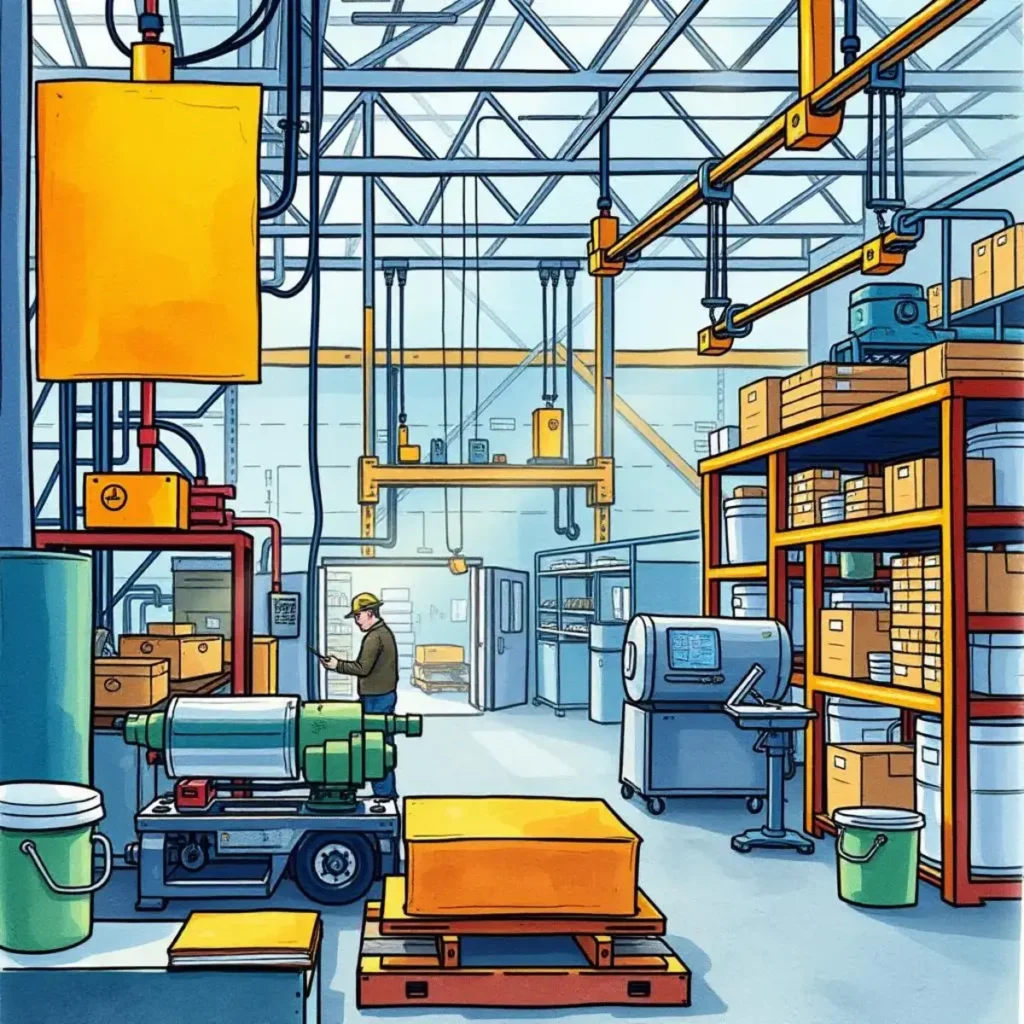

Process flow simulator: Analyze and visualize manufacturing workflows

The process flow simulator helps to optimize processes by simulating inputs, outputs, and resource allocations, improving efficiency in production.

Similar apps

Maximize efficiency in your manufacturing workflows

Streamlined process analysis for optimal performance

Comprehensive input field integration

Our web app features a comprehensive array of input fields, ensuring that users can provide detailed and relevant information regarding each manufacturing process. This includes inputs for process names, descriptions, parameters, and constraints. By capturing all essential details, you enhance the accuracy of simulations and outputs.

Advanced simulation duration settings

Customize simulation durations conveniently with our intuitive interface. Users can specify the time frame in hours within which the simulations should occur. This feature allows for precise analysis of workflows over various time scales, enabling users to optimize processes effectively and forecast potential outcomes accurately.

Resource allocation management made easy

Effortlessly input resource allocation details to ensure that all necessary resources are accounted for during simulations. By enabling users to allocate resources accurately, this feature helps identify bottlenecks and optimize resource utilization for improved process efficiency across manufacturing operations.

Thorough constraints input capability

Define constraints or limitations specific to each workflow directly in the app. These critical inputs allow the simulation tool to consider real-world challenges, ensuring that generated results align closely with operational capabilities and practical scenarios within your manufacturing environment.

Collaboration through team member integration

Enhance collaboration by including team members involved in each process within your input data. This feature allows different stakeholders to contribute their expertise directly into the simulation context, fostering communication and collaboration during process optimization initiatives.

Incorporate previous results for insightful analysis

Users can provide any past simulation results or benchmarks as part of their input. This valuable data enriches the simulation context by grounding it in historical performance metrics, thus facilitating more informed decision-making while pursuing continuous improvement goals.

Additional notes enhance contextual understanding

Add any extra insights or comments that may assist in contextualizing your simulations. This feature allows users to clarify specific conditions or considerations that might affect process outcomes, leading to smarter recommendations driven by nuanced understanding of production dynamics.

Additional information

Best for: Process Simulation Specialist, Lean Manufacturing Engineer, Process Optimization Analyst, Manufacturing Process Engineer, Continuous Improvement Consultant