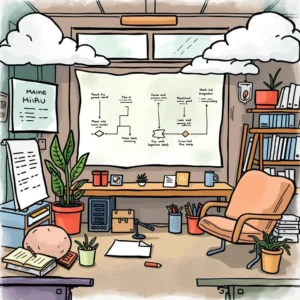

Workflow gap identifier: Highlight inefficiencies in production flow

Identify and analyze workflow gaps with the workflow gap identifier, enhancing efficiency in manufacturing by suggesting actionable improvements.

Similar apps

Identify workflow inefficiencies for enhanced productivity

Streamline your production process with comprehensive analysis

Capture essential process information

Users can efficiently enter critical details about their manufacturing processes, including the process name, current description, and specific issues. This targeted input ensures that every aspect of the workflow is addressed, allowing for a comprehensive understanding of operational gaps.

Set clear goals for improvement

The app enables users to define desired outcomes or goals clearly. By articulating these objectives, Process Analysts and Continuous Improvement Managers can align their efforts to optimize production flow and focus on achieving measurable results within defined timelines.

Analyze team dynamics effectively

Team member involvement is crucial in pinpointing gaps in production flow. Users can input relevant personnel involved in the process, facilitating effective communication and collaboration that assists in resolving identified inefficiencies while considering all stakeholders' insights.

Document key metrics and kpis

Entering relevant metrics or KPIs provides a quantitative basis for analysis. This feature allows Manufacturing Engineers and Operations Analysts to measure productivity levels objectively and ascertain improvement areas effectively, paving the way for data-driven decision-making.

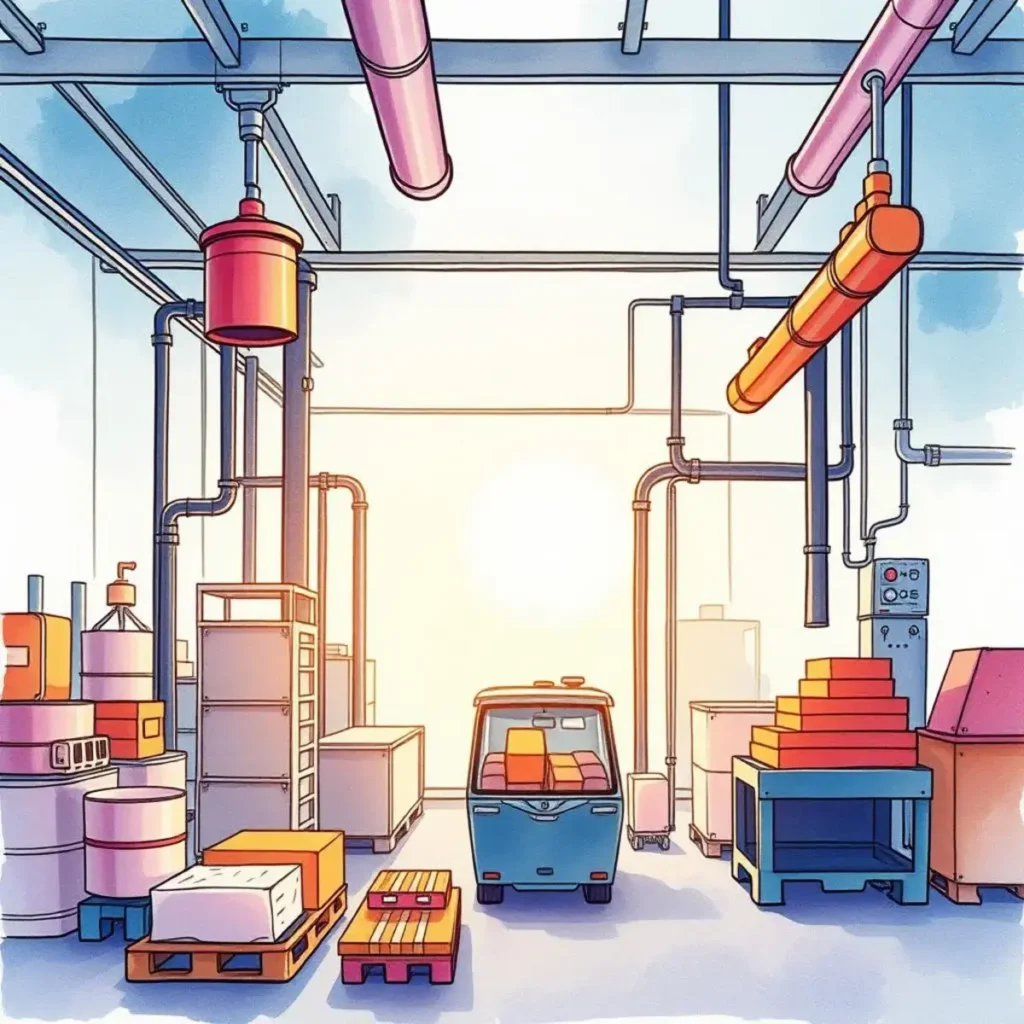

Suggest potential solutions strategically

The ability to propose potential solutions or improvements encourages innovative thinking among users. By inputting these ideas directly into the app, teams can collaboratively identify actionable steps towards optimizing their production processes for enhanced efficiency.

Additional information

Best for: Process Analyst, Continuous Improvement Specialist, Manufacturing Process Engineer, Operations Analyst, Process Improvement Coordinator