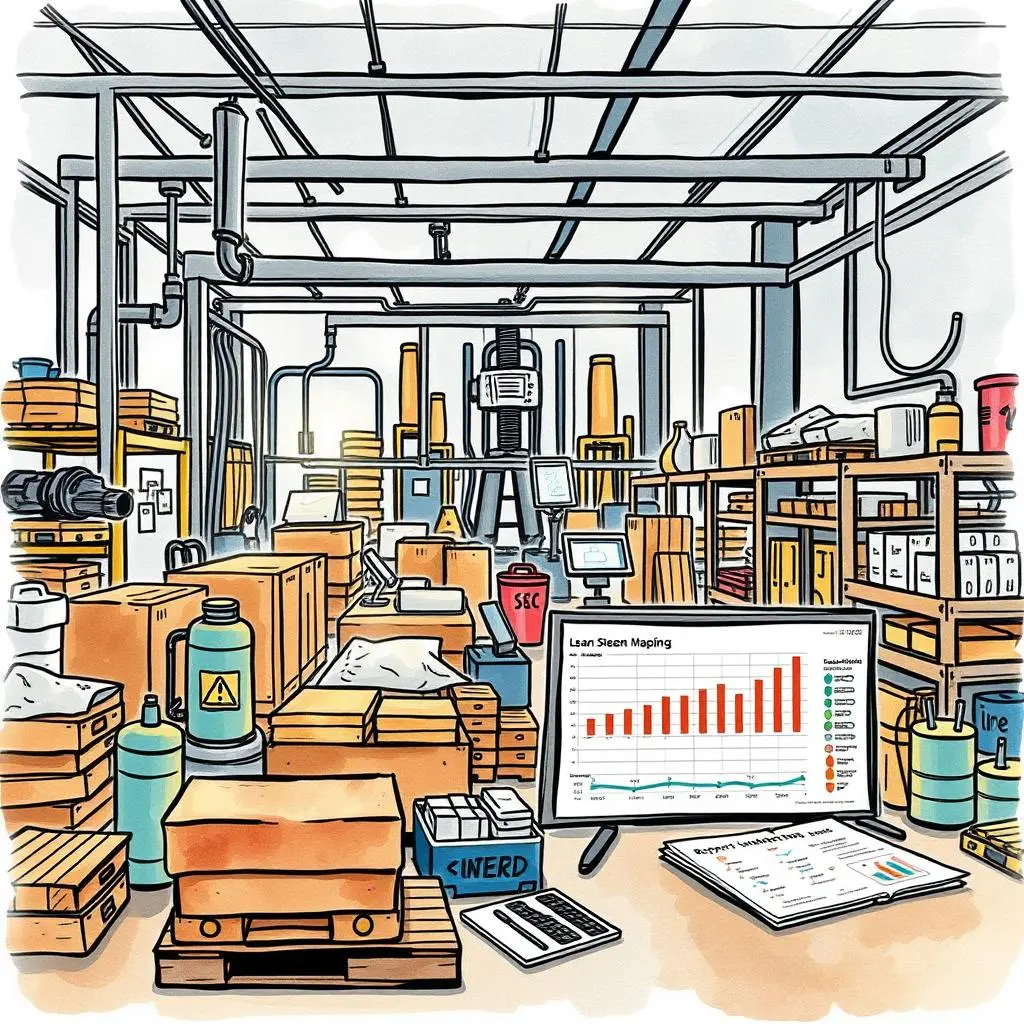

Throughput analysis generator: Report on throughput analysis results

The throughput analysis generator helps you optimize manufacturing workflows by identifying bottlenecks, tracking kpis, and setting actionable goals.

Similar apps

Maximize your throughput analysis with precision reporting

Streamlined data input for comprehensive analysis

Easily enter process details

Effortlessly provide the name of the process being analyzed to guide focused results. Each form field is designed to capture essential information, ensuring your analysis is rooted in accuracy and relevance, ultimately improving the efficiency of your value stream mapping efforts.

Define current and future value streams

Clearly outline both the current and desired future states of your value stream. This feature aids in visualizing progress and identifying critical gaps, enabling more effective strategic planning and decision-making for continuous improvement in manufacturing processes.

Capture key performance indicators

Input essential KPIs that you aim to monitor throughout the analysis. This structured approach not only sets benchmarks for success but also allows continuous tracking of performance metrics, ensuring that all team members are aligned on objectives.

Identify bottlenecks efficiently

Quickly note any bottlenecks or issues disrupting your workflow. By explicitly documenting challenges, you are better equipped to target areas for improvement, enhancing overall production efficiency in your operations.

Generate action items for improvement

Document actionable steps derived from your analysis findings. Entering these action items fosters accountability among team members, driving initiatives forward while ensuring that improvements are systematically addressed within the manufacturing environment.

Articulate expected outcomes clearly

Outline anticipated results from your throughput analysis with ease. Specifying expected outcomes provides a clear roadmap for evaluating success post-implementation and encourages stakeholder buy-in on improvement initiatives.

Capture additional notes seamlessly

Make use of the notes section to record any supplementary information or insights relevant to your analysis. This comprehensive documentation ensures no valuable thoughts are lost while maximizing collaboration across teams involved in process improvement efforts.

Additional information

Best for: Value Stream Specialist, Lean Manufacturing Analyst, Production Efficiency Coordinator, Continuous Improvement Manager, Lean Operations Supervisor