Just-in-time planner: Optimize inventory levels based on user entered data

The just-in-time planner helps streamline assembly workflows, identify bottlenecks, and implement lean principles to boost production efficiency.

Similar apps

Optimize your assembly process with precision

Maximize efficiency and minimize waste in manufacturing

Comprehensive data input fields

The Just-in-Time Planner features multiple data entry fields that capture essential information about your assembly process. Users can provide details on production rates, identified bottlenecks, and proposed solutions, ensuring that no critical aspect is overlooked for optimal inventory levels.

User-friendly interface for seamless experience

Designed with the user in mind, our app offers a straightforward interface that allows Lean Manufacturing Specialists and Assembly Process Engineers to input data effortlessly. This intuitive design ensures quick adoption and minimal training time, facilitating a smooth workflow in busy manufacturing environments.

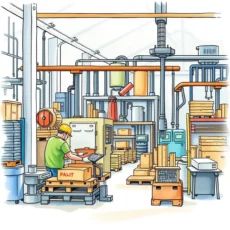

Real-time processing of inputs

Utilizing advanced LLM technology, the Just-in-Time Planner processes your input in real time, delivering actionable insights promptly. Users receive immediate feedback on their provided data, enabling rapid decision-making to address bottlenecks and enhance efficiency within the assembly process.

Data-driven insights for continuous improvement

Harness the power of your collected data with our web app’s focus on generating insights based on lean principles. By analyzing current production rates and suggested improvements, professionals can systematically implement changes that lead to sustained operational excellence in manufacturing processes.

Tailored outputs for specific needs

The app generates customized output texts based on user-entered information, addressing unique challenges in your assembly line or area. Whether you're targeting specific bottlenecks or optimizing production rates, you receive relevant recommendations tailored to your manufacturing context.

Additional information

Best for: Lean Manufacturing Specialist, Process Improvement Engineer, Assembly Operations Analyst, Continuous Improvement Coordinator, Manufacturing Efficiency Consultant