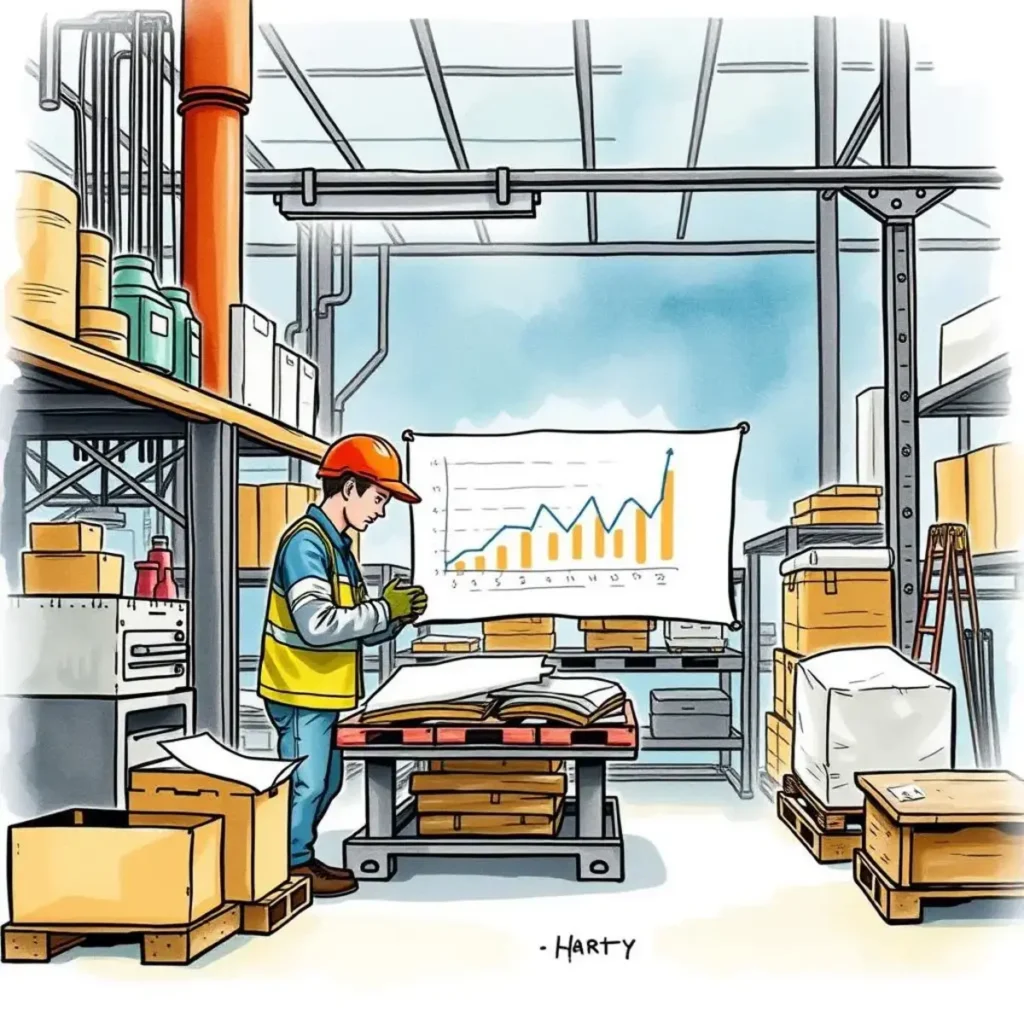

Metric success estimator: Analyze and project performance metrics

Measure root causes and metrics to boost manufacturing success with metric success estimator, ensuring effective analysis and improved outcomes.

Similar apps

Comprehensive metrics analysis for manufacturing

Unlock insights to optimize performance

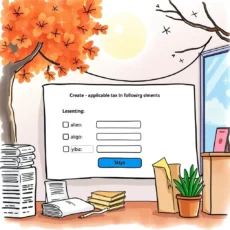

User-friendly text input system

The Metric Success Estimator features a straightforward text input system, allowing users to enter all necessary information for comprehensive analysis. By guiding users through specific fields, the tool ensures that vital details aren't overlooked, leading to accurate and actionable insights.

Detailed root cause breakdown

Users can specify the root cause of production issues directly within the app. This feature empowers Lean Manufacturing Engineers and Process Improvement Specialists to analyze problems critically, identifying key factors that require attention for enhanced operational efficiency.

Customizable performance metrics input

The app lets users define specific metrics they wish to evaluate. This customization allows Quality Assurance Analysts and Continuous Improvement Managers to align their analyses with precise performance goals, ensuring tailored insights that reflect organizational objectives.

Current vs desired performance levels

By enabling users to input both current and desired performance levels, the Metric Success Estimator facilitates targeted assessments. Operations Analysts can easily identify gaps in performance, equipping teams with the knowledge needed to implement effective changes.

Timeframe specification for goals

Users have the ability to set a timeframe for achieving their desired metrics. This feature is essential for planning and executing effective strategies within the manufacturing process, providing clarity on timelines and expected outcomes.

Integration of relevant data sources

The app allows easy entry of relevant data sources or reports alongside other information inputs. This feature enhances analysis accuracy by ensuring all pertinent data is considered, enabling thorough investigations into success barriers.

Team collaboration focused inputs

With options to enter team members involved in the analysis, this tool promotes collaboration among stakeholders. It encourages open communication among Lean Manufacturing teams and Continuous Improvement Managers throughout the issue resolution process.

Identification of potential barriers to success

Inputs concerning potential barriers aid users in foreseeing challenges that might disrupt performance improvements. By addressing these obstacles early in the analysis phase, teams can strategize effectively towards sustainable solutions.

Additional notes for holistic analysis

An additional notes field permits users to capture any supplementary observations or comments relevant to their analyses. This promotes a holistic approach by allowing professionals like Operations Analysts and Process Improvement Specialists to consider contextual elements during root cause evaluations.

Additional information

Best for: Lean Manufacturing Analyst, Continuous Improvement Specialist, Metrics Analyst, Production Quality Engineer, Manufacturing Process Improvement Manager