Equipment efficiency evaluator: Assess and summarize equipment efficiency reports

The equipment efficiency evaluator helps streamline maintenance documentation, assess performance metrics, and suggest improvements for better productivity.

Similar apps

Comprehensive equipment efficiency evaluation for enhanced performance

Streamlined data input for accurate reports

Effortless equipment identification and reporting

Easily enter the equipment name or ID to keep all assessments organized. This feature simplifies report generation, ensuring that each evaluation is accurately linked to the relevant machinery. With precise identification, your maintenance documentation becomes clearer and more effective.

Detailed performance review documentation

Input the performance review date with just a few clicks to maintain a chronological record of equipment evaluations. This allows you to track trends over time, facilitating informed decision-making and enhancing your team's ability to analyze performance changes effectively.

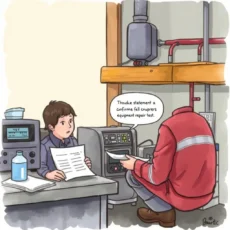

Capture technician insights instantly

Record the maintenance technician's name during evaluations, which adds accountability and context to each report. Understanding who inspected an asset can improve communication and ensure that insights are effectively shared among team members, driving continuous improvement in equipment management.

Thorough metrics tracking for informed decisions

Enter crucial performance metrics, such as efficiency percentages, directly into the app. By capturing key data points, this feature enables your team to identify areas needing attention quickly and promotes timely interventions that enhance operational effectiveness.

Identify issues & malfunctions efficiently

Document any issues or malfunctions noted during the review process for thorough analysis. This feature empowers maintenance teams with the necessary context to address problems proactively, reducing downtime and improving overall equipment reliability.

Actionable improvement recommendations documented

Record recommended actions for improvement directly in the app based on observations made during performance reviews. This structured approach ensures a focus on actionable insights that can lead to enhanced machinery efficiency and reliability within your operations.

Schedule follow-up reviews seamlessly

Input follow-up dates for next reviews effortlessly in order to maintain a proactive approach t o maintenance management. This scheduling feature guarantees that machinery is consistently evaluated over time, allowing teams to stay ahead of potential issues before they escalate.

Additional information

Best for: Equipment Maintenance Specialist, Maintenance Documentation Coordinator, Equipment Performance Analyst, Production Equipment Technician