Performance improvement suggestion tool: Recommend enhancements to supplier processes

Use the performance improvement suggestion tool to record issues, track corrective actions, and enhance supplier quality management in engineering.

Similar apps

Comprehensive supplier enhancement recommendations

Optimize your supplier processes with our tool

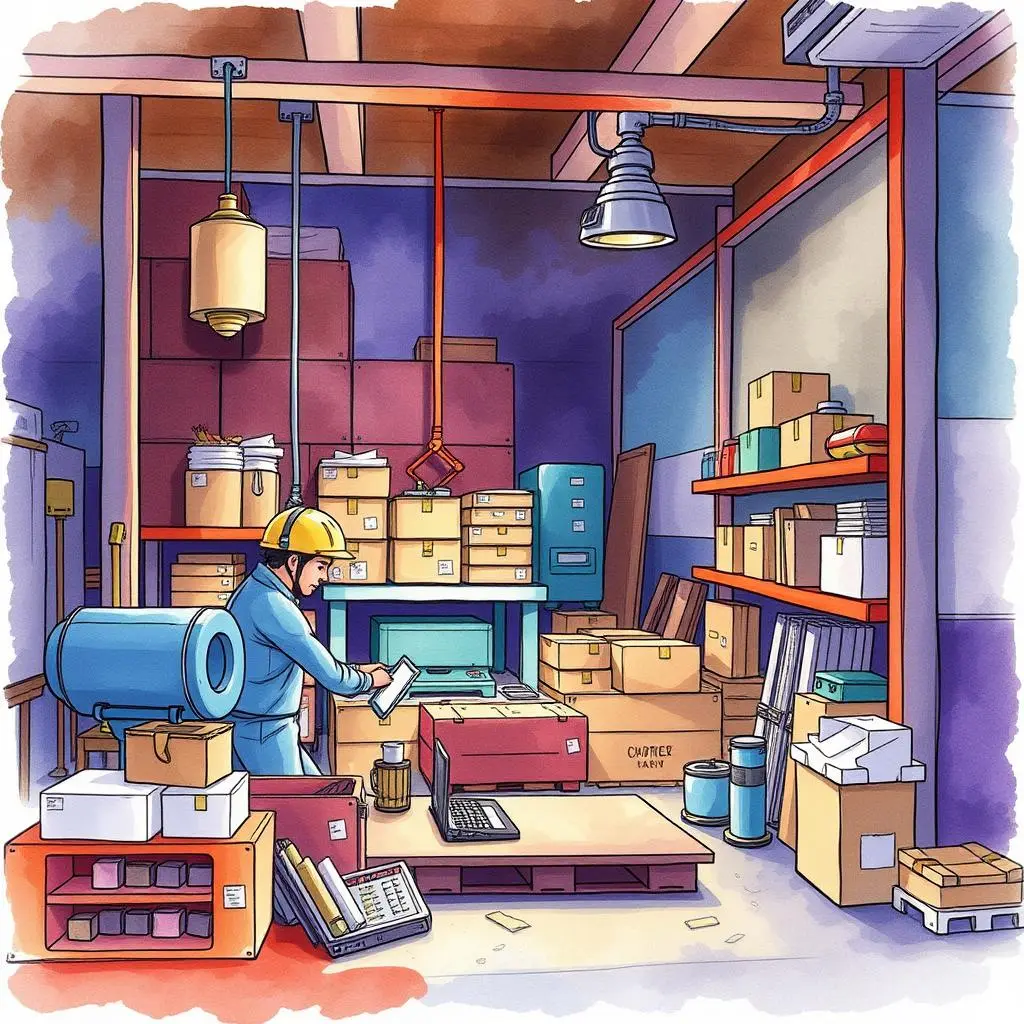

Streamlined input for enhanced accuracy

Our web app features a user-friendly input form that captures essential details. With dedicated fields for names, issue descriptions, corrective actions, and expected outcomes, you ensure that no critical information is overlooked, resulting in precise improvement suggestions every time.

Tailored suggestions for quality management

Leverage our advanced language model to receive customized recommendations based on the specific quality issues you've encountered. By providing detailed insights and corrective measures related to supplier processes, you can effectively elevate quality standards and drive continuous improvement within your supply chain.

User-centric design ensures easy navigation

The intuitive design of our web app focuses on user experience. Each input field is clearly labeled, making it easy for Quality Engineers and Specialists to navigate the form without confusion. This fosters efficiency and encourages thoroughness in submitting quality issues.

Engagement features for enhanced outcomes

With functionally rich fields allowing space for additional comments and suggestions, engage all stakeholders by incorporating diverse perspectives on the corrective action taken. This ensures collaboration across departments while linking expectations to tangible results effectively.

Comprehensive process documentation made simple

Capture all relevant details including the date of issues and actions taken with straightforward data entry fields. By documenting each step meticulously, your organization can create a reliable history of improvements that inform future decisions in supplier quality management.

Additional information

Best for: Supplier Quality Engineer, Quality Assurance Engineer, Corrective Action Specialist, Quality Control Analyst, Supplier Quality Manager