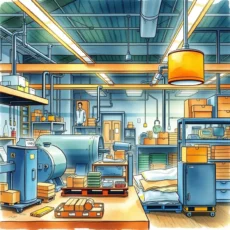

Process flaw identifier: Identify inefficiencies in existing workflows

Identify and improve flaws in your engineering processes with the process flaw identifier. Streamline reviews, propose solutions, and enhance performance.

Similar apps

Identifying process flaws for enhanced workflow efficiency

Maximize your engineering team's productivity by effortlessly pinpointing inefficiencies in existing workflows

Comprehensive text input form

The application features an intuitive text input form that prompts users to enter critical information such as process names, descriptions, and performance metrics. This ensures a comprehensive understanding of the workflow, which leads to more accurate analysis and actionable insights.

Tailored performance metrics assessment

Users can specify current performance metrics and identified flaws or issues directly within the tool. By focusing on relevant data, the application fosters well-informed decisions and helps pinpoint key areas requiring improvement within the engineering processes.

Facilitated improvement suggestions

The web app allows users to propose improvements or solutions alongside their analysis. This feature encourages proactive thinking and empowers teams to take ownership of enhancements, ultimately driving continuous improvement within workflows.

Dedicated team member assignment

Users can assign responsible team members for each process analysis task, ensuring accountability and clear ownership. This promotes collaborative efforts towards resolving identified flaws while streamlining communication within teams engaged in quality process improvement.

Structured review timeline

The inclusion of a review date field allows users to set timelines for follow-ups on proposed solutions. This feature helps maintain progress visibility and encourages timely evaluation of implemented changes, enhancing overall effectiveness in addressing workflow inefficiencies.

Additional information

Best for: Process Improvement Engineer, Continuous Improvement Specialist, Process Analyst, Lean Manufacturing Engineer, Six Sigma Analyst