Process error detector: Identify process errors and suggest fixes

Discover the process error detector for tracking, analyzing, and resolving production errors to enhance quality control and improve processes.

Similar apps

Identifying and resolving process errors: comprehensive solutions made easy

Maximize efficiency in manufacturing and production

Detailed issue input fields

Capture every detail of the process error with our extensive input fields. By providing descriptions, date, time, location, affected products, team members involved, immediate actions taken, suspected root causes, previous occurrences, and additional comments, you ensure that the AI delivers the most relevant suggestions for fixes.

Ai-driven error analysis

Leverage advanced AI technology to identify process errors swiftly. With enriched information from various form fields, receive precise analysis and actionable insights tailored to your specific manufacturing issues. This feature empowers continuous improvement efforts by making data-driven decisions simpler and more effective.

Streamlined root cause investigation

Facilitate efficient investigations into process errors using our structured data input. The platform’s focus on key details helps Quality Control Managers and Continuous Improvement Specialists to quickly understand patterns and delays in production processes, leading to faster root cause identification and resolution.

User-friendly interface for enhanced collaboration

Designed with your workflow in mind, our intuitive interface makes it easy for teams to collaborate effectively. The seamless experience allows multiple users to contribute information regarding manufacturing problems efficiently. This collective approach enhances communication and ensures that all relevant insights are integrated into the problem-solving process.

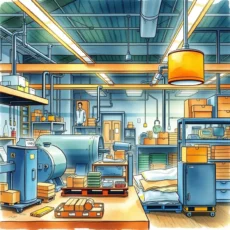

Improved decision-making through comprehensive data

By collating detailed observations through various entry points, this web app empowers stakeholders like Manufacturing Quality Engineers and Process Improvement Coordinators to make well-informed decisions. The increased visibility into issues facilitates smarter strategies for enhancing production quality while reducing error recurrence rates.

Additional information

Best for: Quality Control Analyst, Continuous Improvement Specialist, Root Cause Analysis Engineer, Quality Assurance Manager, Manufacturing Quality Technician