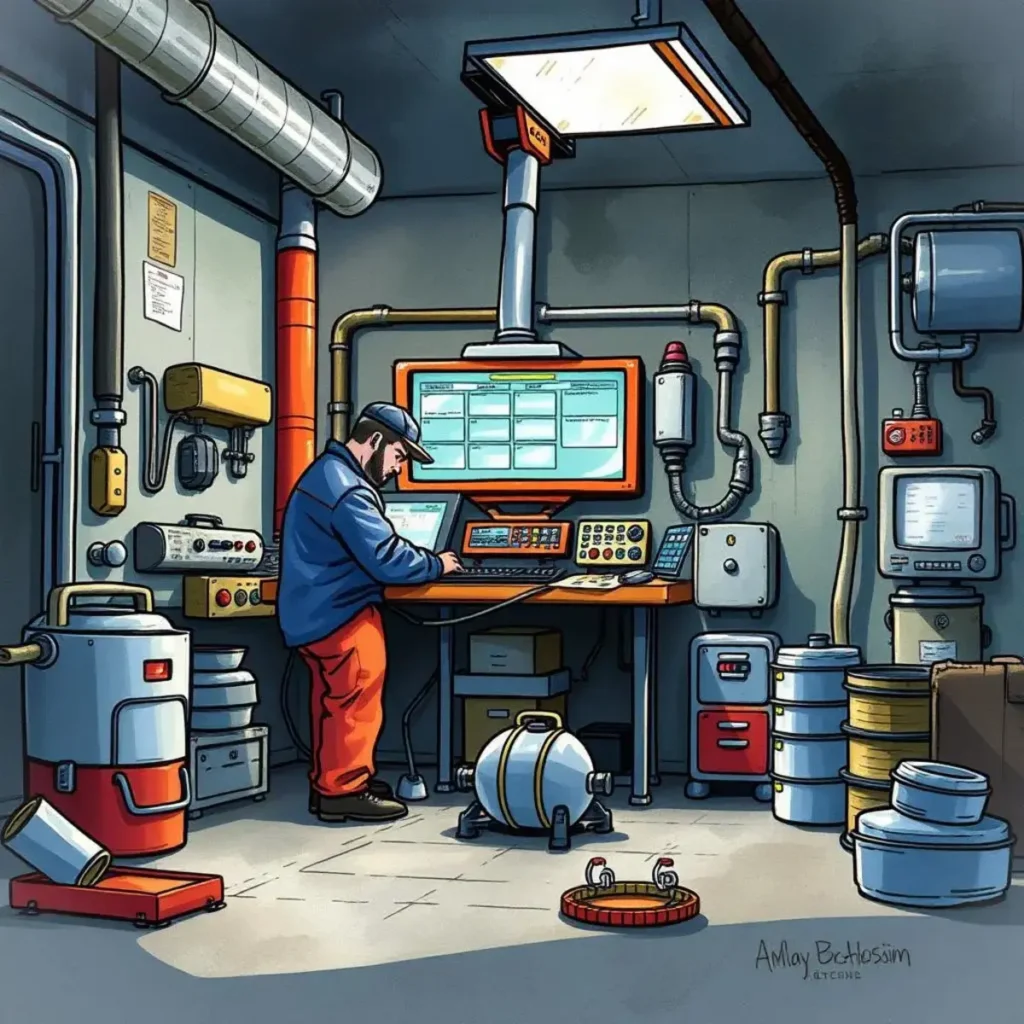

Maintenance calibration assistant: Assist in scheduling maintenance calibrations

The maintenance calibration assistant helps schedule maintenance and calibration efficiently. Track dates, technicians, and priorities with ease.

Similar apps

Comprehensive maintenance scheduling assistant

Streamline your calibration tasks with ease

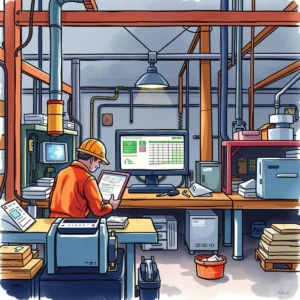

Efficient input of equipment details

Our app allows you to seamlessly input critical information such as equipment name or ID. This ensures optimal management of your assets, helping maintenance staff quickly locate and keep track of all machinery, ultimately minimizing downtime and enhancing productivity.

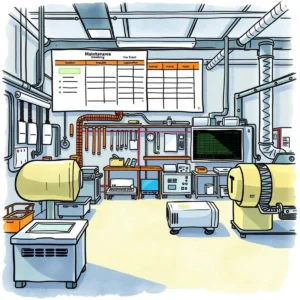

Organized maintenance scheduling process

Easily set maintenance dates and calibrations using our intuitive interface. By entering specific maintenance and calibration dates, you ensure timely checks and balances, which are essential for maintaining machine precision and longevity, thus safeguarding operational efficiency.

Customizable frequency settings

Input the calibration frequency—whether monthly or quarterly—to fit your unique operational needs. This feature lets you tailor maintenance schedules efficiently, ensuring that all equipment is compliant with safety standards while facilitating proactive service actions.

Dynamic technician allocation

Include technician names within the scheduling framework to foster accountability in your team. By designating technicians for each task, you improve tracking for maintenance activities and elevate overall team coordination—promoting effective communication in manufacturing environments.

Informative notes & special instructions field

Our platform includes dedicated fields for notes or special instructions that allow users to provide additional context for each session. This feature aids technicians by highlighting important aspects or unique conditions of equipment needing attention, ensuring thorough servicing.

Historical calibration tracking capability

Log last calibration dates conveniently to maintain a comprehensive history of inspections. This fosters an efficient review process, ensuring all standards are met while facilitating periodic evaluations - crucial for meeting compliance requirements in manufacturing sectors.

Additional information

Best for: Calibration Technician, Equipment Maintenance Planner, Maintenance Scheduler, Calibration Specialist, Equipment Reliability Engineer